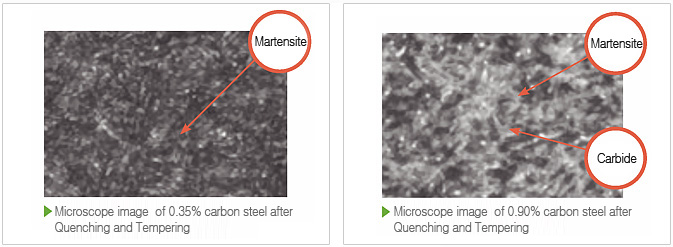

Heat-treating method in which mid- and high-carbon and structural alloy steel are quenched from austenitic temperature to give martensite structure. Temper below sub-critical temperature to give certain toughness.

OPERRATIONAL PROPERTY

- + Short process time

- + Simpler control than carbo kind treating

- + Easy to reach wanted structure & hardness

APPLICATION

- + Automotive (plates, gears, parts etc.)

- + Industrial, vessel & aircraft

- Low vacuum state process using nitrous oxide

Operational property

- + Precise control on diffusion layer

- + Precise temp control offers deformation stability

- + Heat treating stainless

Application

- + Automotive (plates, gears, parts etc.)

- + Die Casting / Plastic injection molds

- + Industrial, electric parts

- + Mold & Dies

FEATURE

- + N2 potential control with H2/O2 sensor, Phase control on user demand

- 1) Gas nitriding(phase control)

- 2) Gas nitrocarburizing

- 3) Gas oxynitriding

- 4) Stainless nitriding(S-Phase)

![Plot No. 126, Samathuvapuram, Mappedu, Ulundai[Post] Thiruvallr [TK && Dist] Tamilnadu, India Tel. +91-44-2769-9814 COPYRIGHTⓒ 2013 DONGWOO SURFACETECH(INDIA) Pvt.Ltd. ALL RIGHTS RESERVED.](../images/common/copyright.gif)