- Low pressure atmosphere for heat treating, quenched in same position. Easy control and maintenance.

- + Single chamber

- + Switchable cooling gas flow (up&down)

- + Compact size(inner heat exchanger)

- + Simple design, low maintenance cost

- + AGING

- + HARDENING

- + SOLUTION ANNEALING

- + BRAZING etc.

- + HIGH SPEED STEEL (SKH51, 55, 57 etc.)

- + STAINLESS STEEL

- + TOOL STEEL

- + TITANIUM ALLOY etc.

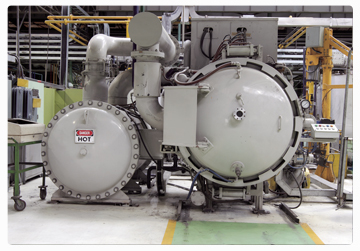

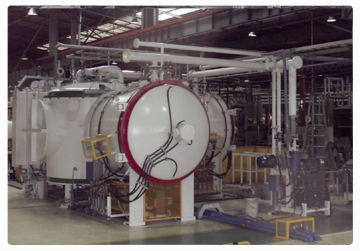

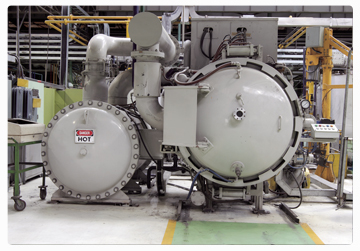

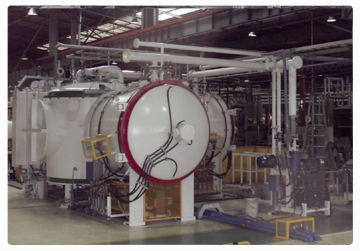

- Separated chamber for heating and cooling. Higher cooling efficiency than a single chamber. Various types of heat treating possible for different demands.

- Either gas or oil cooling can be chosen depending on size of the work piece and heat treating method. Cooling pressure with gas can be operated up to 10 bar.

- + Faster cooling(than 1 chamber type)

- + Gas, oil or salt quenching

- + Suitable for large charge and molds

- + AGING

- + HARDENING

- + SOLUTION ANNEALING

- + BRAZING etc.

- + HIGH SPEED STEEL (SKH51, 55, 57 etc.)

- + STAINLESS STEEL

- + TOOL STEEL

- + TITANIUM etc.

- Non-equilibrium, boost-diffusion carburizing process in which steel being processed is austenitized in a rough vacuum, carburized in a partial pressure of hydrocarbon gas, diffused in rough vacuum and then quenched with gas.

- + High concentration carburizing

- + No intergranular corrosion

- + Carburize small holes and stainless steel

- + High productivity-high temp, less time

- + No emission

- + Clean environment

- + Oil or Gas cooling

- + Tempering/Quenching, Brazing, Gas cooling/Quenching, Oil Quenching, etc.

- Ion nitriding is an extension of conventional nitriding processes using plasma discharge physics.

- In a vacuum, high-voltage electrical energy is used to form a plasma through which nitrogen ions are accelerated to impinge on the work piece.

- Ion bombardment heats the product, cleans the surface and provides active nitrogen.

- + Batch type(in&out, straight), vertical

- + Ion plasma

- + Low temp treating using NH3, RX Gas

- + Technology management friendly

- + Wear, corrosion, fatigue resistance

- + Short process time(0.5~3h)

- + Use NH3, endothermic Gas

- + Forms Oxidized layer at the outer layer for enhanced corrosion resistance

- + Wear, fatigue resistance

- + Fine color(dark blue)

- + Forms plasma using N2, H gas under vacuum

- + Environment friendly process

- + Less distortion(relatively low temp)

- + Process variable limited to mixed gas, pressure and temperature

- + Simple property control

![Plot No. 126, Samathuvapuram, Mappedu, Ulundai[Post] Thiruvallr [TK && Dist] Tamilnadu, India Tel. +91-44-2769-9814 COPYRIGHTⓒ 2013 DONGWOO SURFACETECH(INDIA) Pvt.Ltd. ALL RIGHTS RESERVED.](../images/common/copyright.gif)