- Requires less room than continuous batch furnace, with fully automatic continuous heat-treating process designed to maximize productivity for your site.

- Provides stable atmospheric conditions while work piece is transferred inside the furnace.

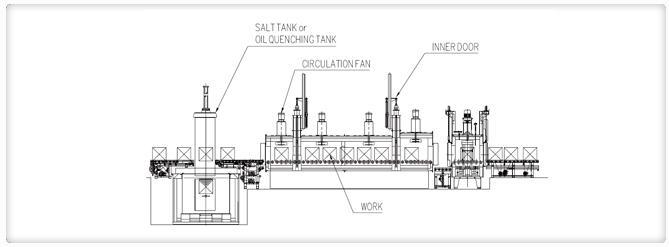

- Semi-continuous batch furnace consists of inserting, pre-heating, heat-treating furnace and quenching with oil (or salt) storage tank.

- Supplementary installation of pre-washing, washing or tempering furnace also available.

FURNACE FEATURE

- + Easy quality control, High reliability

- + High energy efficiency, Full automatic Low operation cost

- + Easy control and maintenance

- + Suitable for items which need long process time

- + Suitable for continuous heavy charges and items

PROCESS OPTIONS

- + Carburizing, Carbonitriding, Bright Quenching, Annealing etc..

REFERENCES :TOTAL 24 FURNACES IN SERVICE

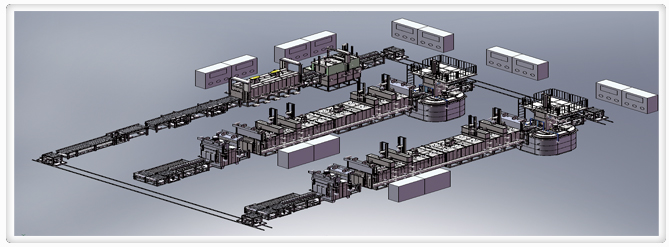

- Continuous furnace consisting of inserting, pre-heating, heat-treating furnace and quenching, with oil (or salt) storage tank.

- Supplementary installation of pre-washing, washing or tempering furnace also available.

- Roller systems can vary from the linear formation of pusher type furnaces, reducing transferring issues and requiring 40% less floor space. No need for an empty tray insert for charging and discharging.

- A different work piece with an alternate heat treating pattern can be input while furnace is treating other work pieces.

- Suitable for work pieces that require a long heat-treating period and high quality.

FURNACE FEATURE

- + Most typical continuous heat treating furnace

- + Easy quality control, High reliability

- + High energy efficiency, Full automatic

- + Low operation cost

- + Easy control and maintenance

- + Suitable for items which need long process time

- + Suitable for heavy charges

PROCESS OPTIONS

- + Carburizing, Carbonitriding, Bright Quenching, Annealing etc.

References

ABROAD- + HYUNDAI MOTORS(INDIA, CHINA,MEXICO, CZECH)

- + DOW A THT AMERICA(USA)

- + DOW A, HONDA, AW, MITSUBISHI (JAPAN)

- + BEIJING MOBIS, DAEWOO (CHINA)

- + DAEWOO (INDIA)

- + DAEWOO (RUMANIA)

- + HYUNDAI MOTORS, HYUNDAI POW ERTECH

- + KIA MOTORS, WIA, GM-DAEWOO MOTORS

- + S&T Heavy industry, Sunil Heat treating, NEO-OTO

- + DIC

![Plot No. 126, Samathuvapuram, Mappedu, Ulundai[Post] Thiruvallr [TK && Dist] Tamilnadu, India Tel. +91-44-2769-9814 COPYRIGHTⓒ 2013 DONGWOO SURFACETECH(INDIA) Pvt.Ltd. ALL RIGHTS RESERVED.](../images/common/copyright.gif)